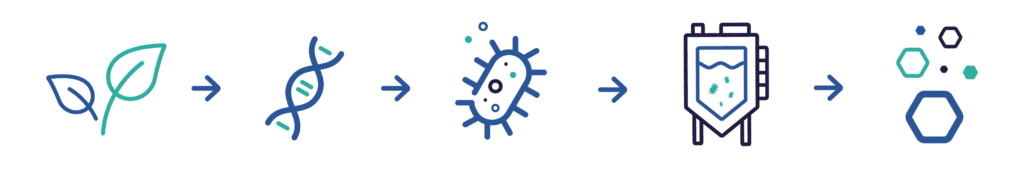

EV Biotech is partnering with Delft Advanced Biorenewables (DAB.bio) to design a microbial strain and process for the sustainable and cost-effective production of a bio-based fragrant monoterpene to be used in insect repellent or perfumery.

The monoterpene typically inhibits microorganism growth and production, necessitating continuous removal from the fermentation broth. Extracting a product continuously from a fermenter is impractical with existing technology. DAB.bio’s elegant solution, known as Fermentation Accelerated by Separation Technology (FAST), separates the product from the fermentation in the main vessel – without moving parts or membranes. In doing so, FAST enables longer fermentation durations and simplifies downstream processing (DSP), making monoterpene production both more sustainable and more cost-effective.

Bio-based alternatives to fossil fuels are essential for global sustainability, but they are often cost-prohibitive. DAB.bio begins with the end in mind. Their unique demonstration scale bioreactor technology turbocharges fermentation processes and decreases product costs by up to 50%. By transforming the economics of production, DAB.bio’s technology can unlock the promise of biomanufacturing across a wide array of markets and goods.

EV Biotech creates microbial production platforms for high-value chemicals: a bio-based alternative to synthetic chemical production.

“By combining classical fermentation with computational modeling, we can predict what chance of success certain strategies in strain development have. As a result, only the possibilities with the highest chance of success will be carried out, reducing the work by 90%. Additionally, the computational algorithms can predict bottlenecks during the development before running into them, creating risk mitigation in strain engineering.”

– Linda Dijkshoorn (CEO EV Biotech)

Alignment is essential to co-develop an efficient and cost-effective strain and process for biobased production.

“With EV biotech’s use of predictive algorithms to design and develop microbial strains, and DAB.bio’s expertise in process engineering, we can develop a robust strain and process combination that maximizes product formation during fermentation and facilitates recovery. By working together, we can enable the economics of more sustainable green chemicals.”

– Kirsten Steinbusch (CTO DAB.bio)