A world without plastics seems unimaginable today. If you read this blog, it is almost sure that you are staring at a device that contains plastic while wearing plastic-containing clothes. Maybe you even sit on a chair made of plastic while chewing on plastic gum. Plastics have made many developments possible, from packaging and transportation to modern medicine. This super material has all the properties one could ask for. It is strong, lightweight, easily deformable, water-resistant and cheap. But also, it doesn’t degrade… We produce more plastic waste each year, and the bulk of it ends up in landfills, is incinerated, or leaks into the environment. Eventually, plastic ends up in our oceans, where they comprise 80% of all marine waste. Public awareness of the plastic waste crisis is rising, and governments are starting to come up with laws to mitigate the use of single-use plastics. But what the world really may need is a plastic substitute with all the positive characteristics of plastics but that can disappear from the environment altogether. Let us introduce you to our candidate, PHA.

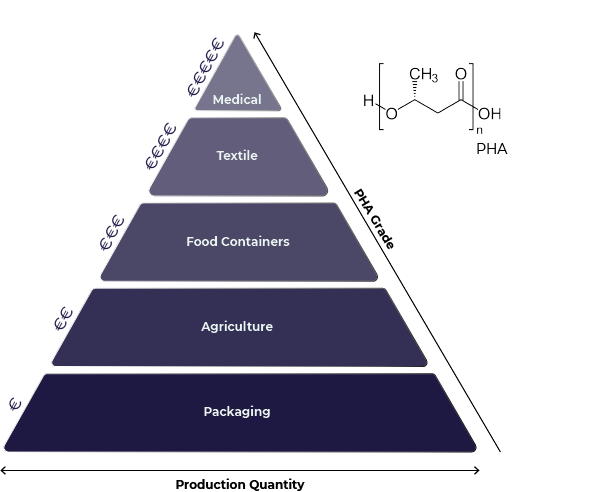

PHA or ‘polyhydroxyalkanoate’ is a polymer family that is naturally produced in numerous bacterial species as an energy reserve, just like fat reserves in us humans. Next to being bio-based (it is made by organisms), PHA is biodegradable, meaning it decomposes over time. PHAs exist in a wide array of types and compositions from which an appropriate type can be produced depending on the desired application. From disposable bags to high-end medical implants, PHAs have been shown capable of doing the job.

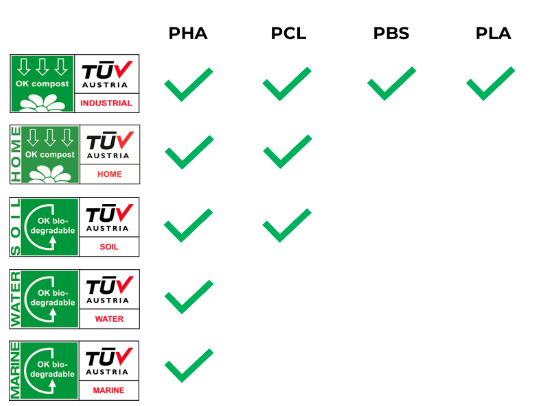

The pool of bio-based biodegradable plastics contains more types than PHA alone. Some of which, like polylactic acid (PLA), have already established a strong position in the market. Although PLA-based products claim to be biodegradable, they only are so when collected separately and treated in a specific industrial composting facility. So if a bioplastic article carries the claim ‘biodegradable’ or ‘compostable’ on itself that doesn’t mean much. Their environmental degradation time can be just as long as petroleum-based plastics making them just as polluting. PHAs, however, are fully entitled to the compostable claim as they are compatible with industrial composting facilities, but next to that, they will also simply decompose in ambient environments, like the soil and even the ocean. In addition, PHA can be recycled for new applications and returned to its building blocks to be used as nutrients for living organisms (biodegraded).

PHA is our chosen candidate to solve the plastic crisis. They have all the necessary characteristics to substitute conventional plastics. They meet the demand of today’s society as well as the political agenda and will comprise a substantial share of the bioplastic economy. It is, therefore, no surprise that the market predictions on PHA supply and demand are very optimistic. When widely adopted, PHAs can have a major impact in reaching our goals for a sustainable future for polymers, respecting the environment and our future generations.

Written by Julien van Schaik